Heat Siphons Low Pump Watt Heat Exchanger

Water on the Outside, Hot Refrigerant gas on the Inside:

There are basically two types of heat exchanger designs in air-to-water (pool heater) heat pumps: Tube-in-tube and tube-in-shell.

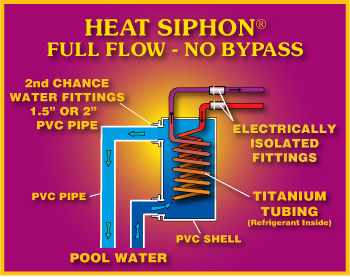

From the very first design Heat Siphon chose the more costly but much more efficient FULL FLOW tube-in-shell heat exchanger so high volumes of water could flow around the outside of the tube coil with almost no back pressure and required no bypass valve at all.

The heat transfer required more tubing and a shell but it eliminates all the extra pool pump watts.

Most other pool heat pumps use the low cost old tube-in-tube design. One long tube is placed inside of another and water flows through the small inside tube (usually 3/4" to 1" in diameter) while the refrigerant gas flows in the space between the two tubes.

It was originally developed for use in low water flow building heating and cooling systems using 5 to 10 gallons per minute. For a pool heater, this design requires most of the 40 to 80 gallons per minute swimming pool pump flow to be by-passed which creates back pressure and loads down the pool pump.

On 1.5 or 2 horsepower pumps this can amount to an additional 10 to 25% more watts consumed just to overcome the spring force in the bypass valve.

HEAT SIPHON HISTORY - Back in 1983, In order to manufacture Heat Siphon's tube coil-in shell heat exchanger, the founders had to design and build their own tube coiling machine. It took over a year to perfect, including many design revisions and fabricating and machining many of the parts on a small milling machine in house. That coiling machine has been refined but is still in use today - a quarter century later.